Customers' requirements are as individual as our services. We develop effective configurations for lightweight composites, provide product and process support from the very beginning till the manufacturing process as well as trainings. Our services bring added value and are not only customized but also sustainable, cost-effective and environmentally-friendly.

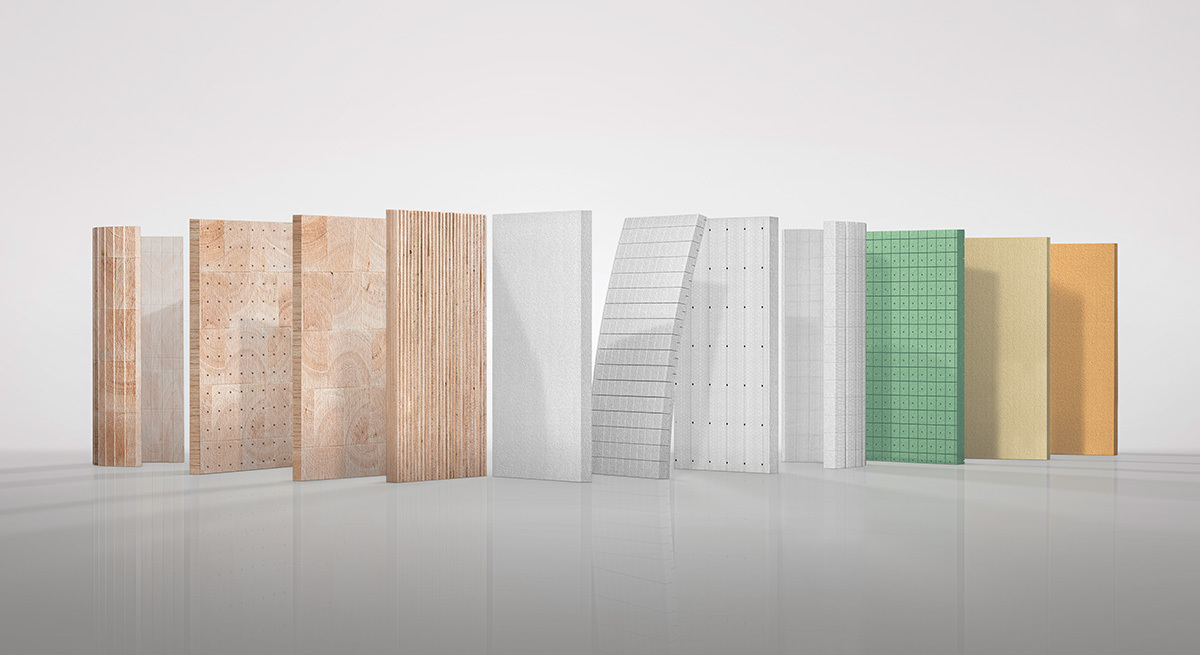

What is a core material and a sandwich construction? Components manufactured as so called sandwiches are made by attaching two thin skins to a lightweight core. Such sandwich panels efficiently distribute mechanical properties in the component's structure. Bending stresses are maximum at exterior, so the further away from the centerline, the higher the impact of the material's bending strength and stiffness. It's all about concentrating the material's stiffness and strength at the exterior of your structure.

This concept is by the way not a new invention - look how extensively nature uses the skin/core concept. Just think of the bones of a bird.

Lightweight sandwich structures allow building high-performing systems that would not be possible in conventional design.

Lightweight vehicles consume considerably less fuel and can get more payload capacity.

The handling of moving parts is greatly facilitated by reduced weight, so processes become faster at less effort.

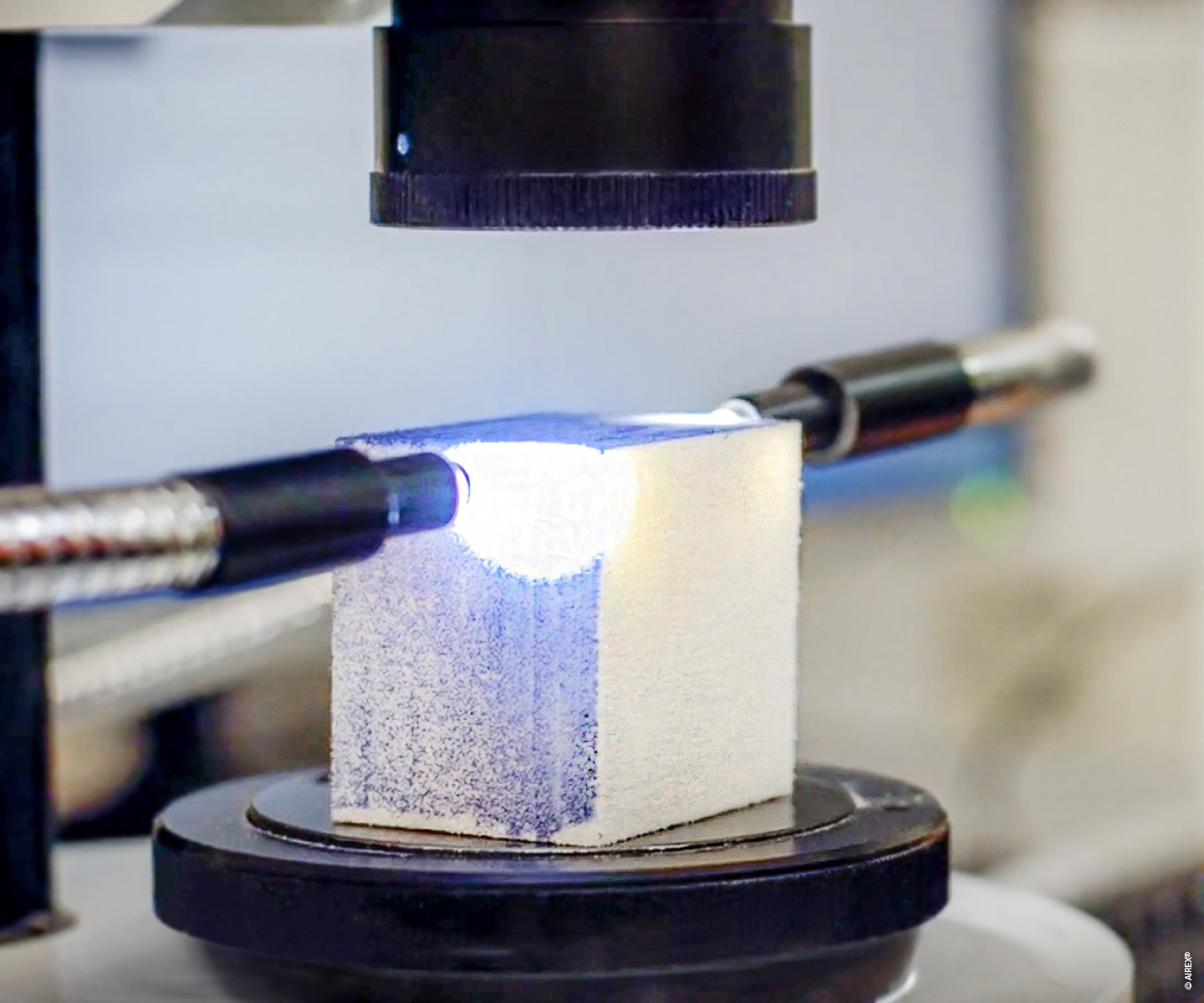

Materials and components testing is daily work for our engineers and process specialists. They test compliance with ASTM, EN, ISO and other recognized standards and use our extensive equipment to perform even custom tests in individualized manner.

Many official product certificates are available upon request. If custom certificates are required, they can be issued by our own test laboratories as well as in close cooperation with our partners. We conform to recognized standards, e.g. ABS, DNV.GL, Lloyd's Register, Korean Register and customer specifications.

Our engineers and process specialists provide on-site customer assistance whenever their support and engineering skills are needed throughout the process:

Reach out for us if you want to find out more about our product technologies and services.