The LANTOR® Composites division offers a comprehensive range of innovative nonwoven solutions for the Composites (Fibre Reinforced Plastics) industry.

LANTOR® Composites has built a solid reputation ever since she introduced nonwoven core materials as a time and cost-saving solution to the Composites industry.

In close co-operation with the world's leading end-users and institutes, successive generations of LANTOR® mat products have been developed for specific applications.

The materials are suitable for commonly used production methods:

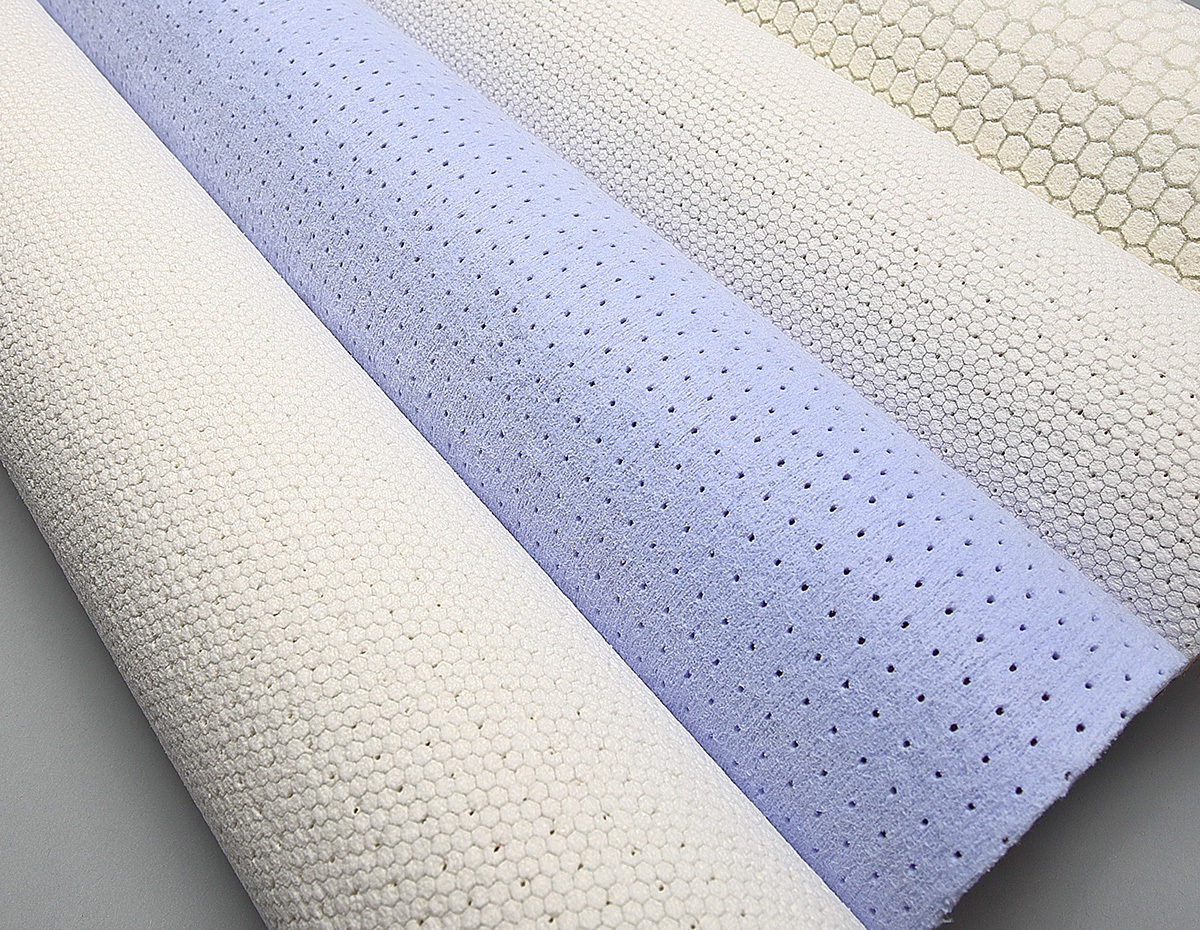

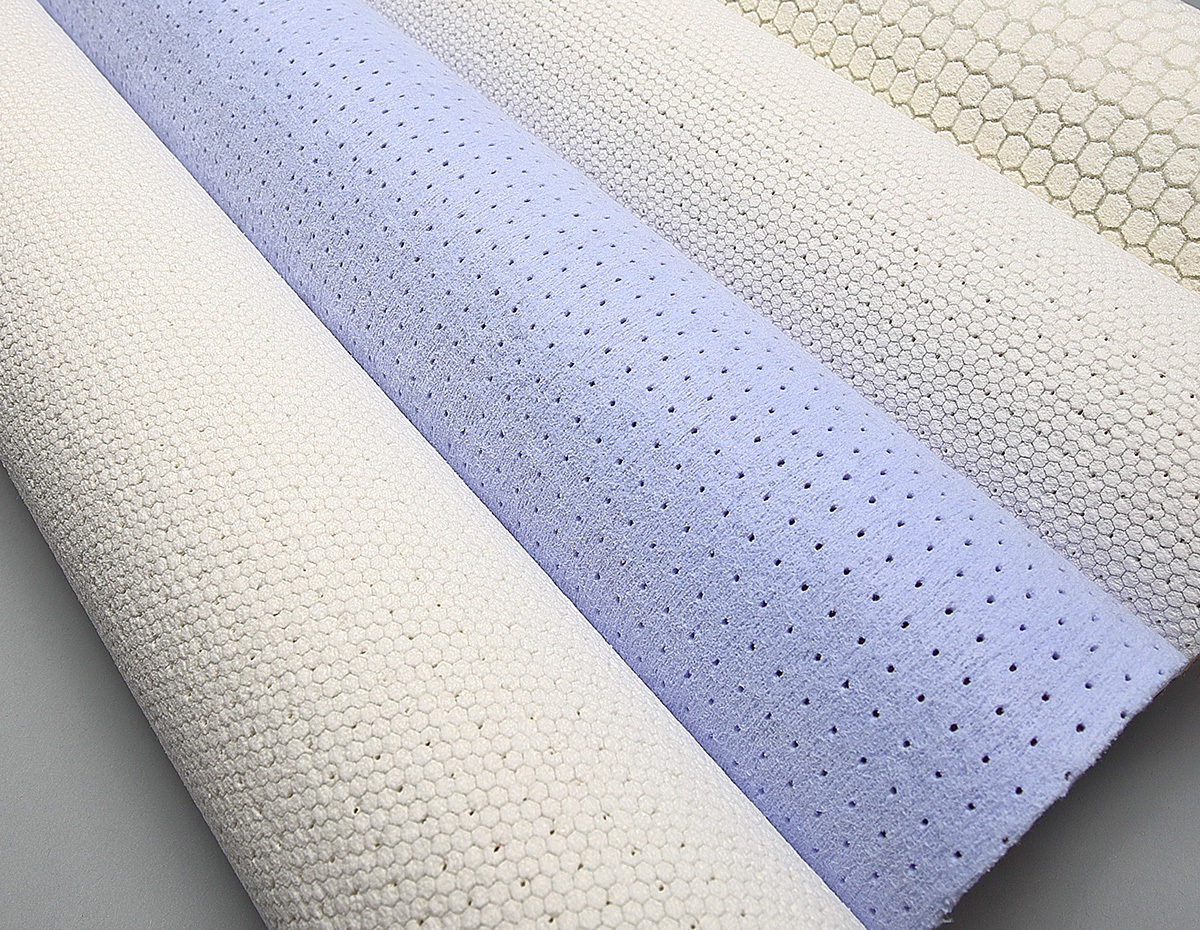

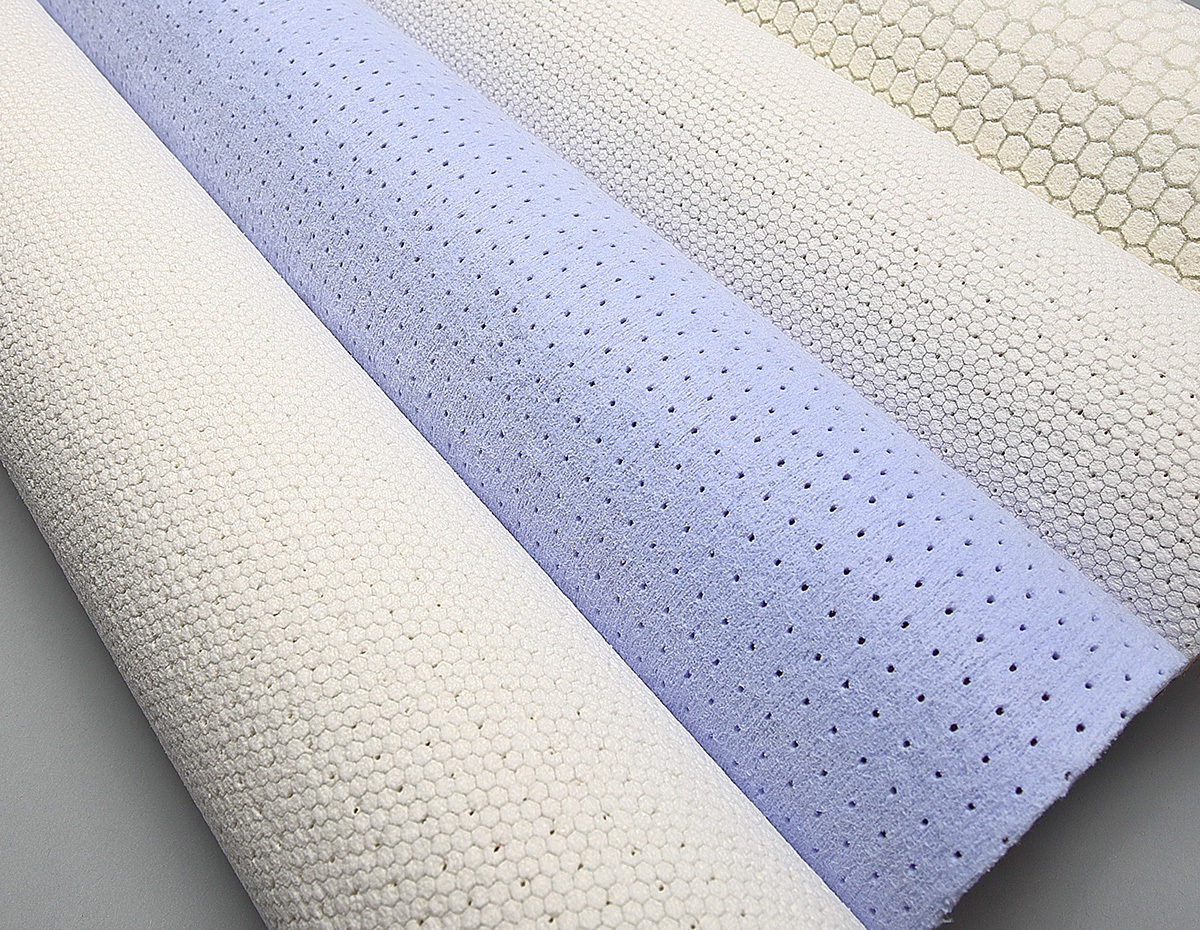

For decades, Coremat® has been considered the world standard for flexible bulker mats and print blockers used in hand lay-up and spray-up processes. All Coremat® grades consist of a polyester nonwoven containing microspheres. They offer a cost-effective increase in stiffness and weight-savings in materials and an excellent surface finish

More

For closed mould processes, LANTOR® offers a unique and patented product range of core materials that are both flexible and compression resistant. During the infusion process, the Soric® core works as a flow medium and enables steady and inter-laminar impregnation. Once the process is finished, the impregnated Soric® is an excellent bonded honeycomb structured core that offers weight reduction and cost-efficient stiffness.

More

Finishmat® is the LANTOR® range of surfacing veils for the composites industry. Finishmat® veils are used to improve surface cosmetics, create better chemical resistance, or reduce the abrasion of composite structures. Each LANTOR® Finishmat® offers good and even impregnation and is suitable for several production processes and applications.

MoreMake your choice out of the broadest portfolio of high-performing and sustainable core materials made of rigid foams and balsa wood.

If you want to find out more about our products or you need to get any further information - just reach us.